Weitmann & Konrad GmbH & Co.KG

Booth number: A 661

weko.net

About us

The contactless minimal application of fluids and powders on a wide variety of materials is our specialty. You save fresh water, chemicals and energy with our systems. A clear cost-benefit for you and for our environment. Tests for sprayability and trials outside your running production - we do it for you in our WEKO-TechnologyCenter.

Address

Friedrich-List-Straße 20-24

D-70771 Leinfelden-Echterdingen

Germany

E-mail: info@weko.net

Phone: +49 711 79880

Internet: weko.net

13 Jalan Bukit Merah

#17-5036 Singapore 150013

Singapore

E-mail: wbenze@gmx.net

Phone: +65 97 887708

Contact person:

Mr. Stefan Käszmann

E-mail: stefan.kaeszmann@weko.net

Products & Services

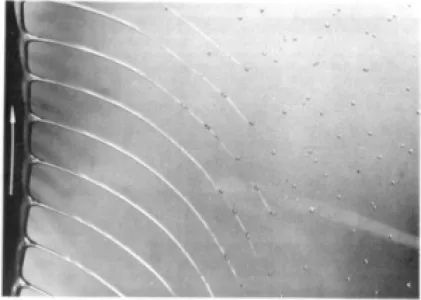

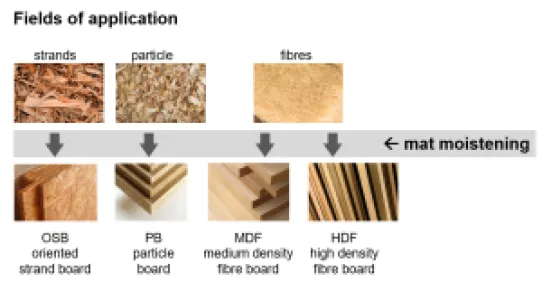

A controlled and uniform moistening of the top layer of the fiber, particle or chip cake evaporates due to the heat of the press. This steam shock effect activates the adhesive up to 30% faster and thus reduces the correspondingly required pressing time.

This enables higher production speeds.

The precise application of moisture also leads to higher board density (strength), the surface becomes more uniform and, as a result, fewer grinding operations and material removal are necessary.

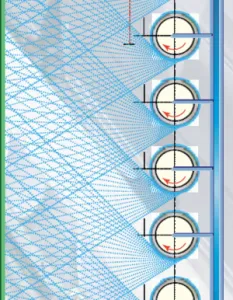

The decisive factors in moisture and release agent application are uniform application to avoid optical imperfections. This is because a poorer surface appearance must be sanded down again afterwards. Alternative spray application systems sometimes have cloudy and streaky application patterns and vary the application quality, especially at different speeds.

Your advantages at a glance

Up to 30% higher line productivity

Increased board quality (density, flexibility, surface quality)

Lower material consumption for the same board thickness

Designed for year-round 24/7 operation

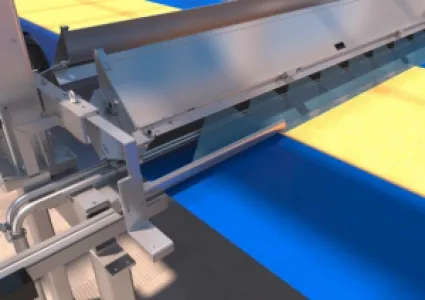

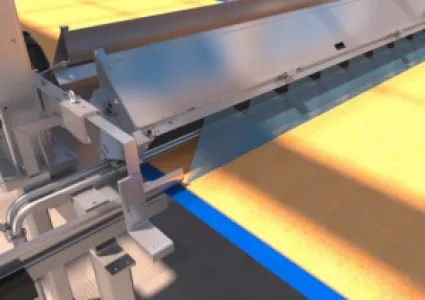

Contactless and precise application on belt and mat

Automatic size adjustment (option)

Automatic speed adjustment

Automatic height adjustment (option)

Various control station connections available

and much more.

How can productivity be increased in the manufacture of wood fiberboard?

Release agents prevent the material from sticking to the press belt and enable uninterrupted panel production. This is combined with controlled moistening of the top layer, which activates the glue in the press up to 30% faster. This shortens the pressing time accordingly and thus increases the production speed. In addition, the precise and even application of moisture leads to a higher board density of the top layers and a more even surface, which means that less sanding is required.