Dieffenbacher GmbH

Booth number: A 635

www.dieffenbacher.com

About us

DIEFFENBACHER is a leading manufacturer of complete production plants for the wood-based panels industry. We combine technologies, processes and application know-how with extensive client collaboration to create advanced solutions and to help our customers achieve their business goals. Our smart plants for the production of particleboard, MDF, OSB, LVL and wood fiber insulation boards provide a decisive edge in the market. Our digitalization platform EVORIS sets new standards in the industry. AI-supported analysis of live data help our customers better understand and control their plants and make important decisions more quickly. 1,900 employees at 20 production, service and sales locations help our business partners benefit from local and global expertise. As an independent family business in its fifth generation, we’ve stood for reliable partnership and continuous progress for over 150 years.

Address

Heilbronner Str. 20

75031 Eppingen

Germany

E-mail: wood@dieffenbacher.com

Phone: +49 7262 65-0

Internet: www.dieffenbacher.com

303, 3rd Floor Brigade Rubix No. 20, HMT Factory Main Road, Jalahalli Post

Jalahalli Post

560013 Bangalore

India

E-mail: info_india@dieffenbacher.com

Phone: +91 80 29723200

Internet: www.dieffenbacher.com

One Pacific Place 18th Floor Unit 1802

Sukhumvit Road, Khlong Toei Sub-District

10110 Khlong Toei, Bangkok

Thailand

Phone: +66 65 459 6949

Internet: dieffenbacher.com

D-19-03, Menara Mitraland

No. 13A, Jalan PJU 5/1, Kota Damansara, PJU 5

47810 Petaling Jaya Selangor

Malaysia

E-mail: dap@dieffenbacher.com.my

Phone: +60 3 7629 4887

Internet: www.dieffenbacher.com

Contact person:

Area Sales Director Holger Ries

Area Sales Director

E-mail: Holger.Ries@dieffenbacher.de

Phone: +49 171 5592 518

Products & Services

Work with us to build advanced complete plants for the production of particleboard, MDF, OSB and LVL boards and gain a decisive edge in the market. Rely on service that can do more and modernization solutions for tomorrow.

Together, let’s find better solutions to make your production profitable and fit for the future. Core components are:

Chipper, flakers, hammer mills and other machines for wood

preparation

Machines for raw material screening and cleaning

Dryer and grader

Environmental Technology

Gluing systems

Spreading systems

Continuous presses (CPS+ and ContiPlus)

Multi-Opening presses

Handling and finishing

Energy plants

Complete plant solutions (CEBRO)

Digitalization solutions (EVORIS)

CEBRO - Your smart plant from Dieffenbacher

EVORIS

New Wireless STS

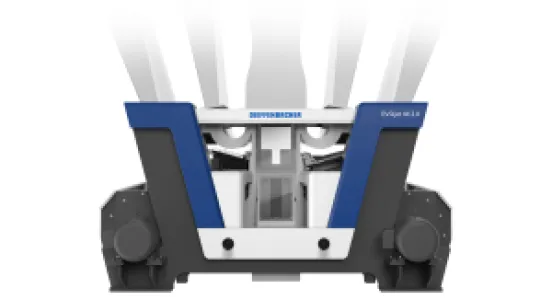

CPS + Continous Press System

The gold standard for efficient continous press systems reduce your life cycle costs; save wood, glue and energy; and boost your throughput of high-quality PB, MDF, OSB and LVL boards.

Benefits:

Low sanding allowance due to the Double-Hinge Infeed System

Low glue consumption due to Parallel Press Gap System

Optimal thickness tolerances due to proven CPS+ Thickness Control System

Lifetime heating platen concept with separate protection plates